- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

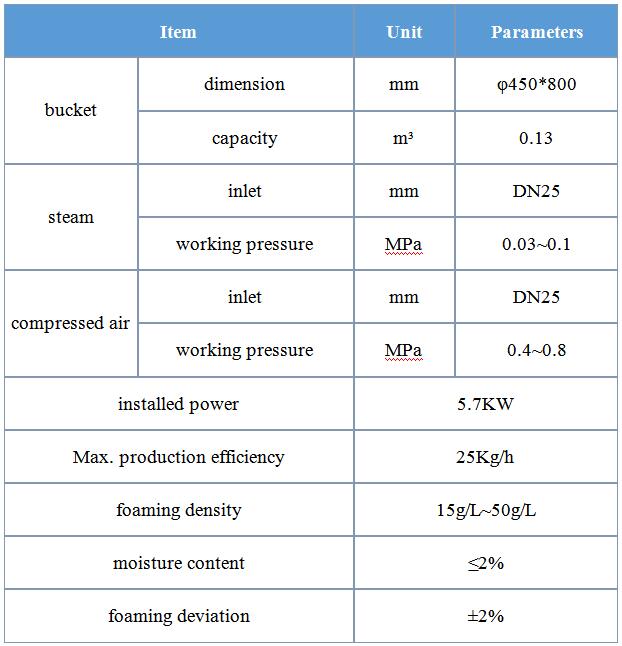

The Batch EPS pre-expander Machine with one button start and easy operation. According to process requirements, mixing time and steam heating time can be set in time. Closed constant pressure foaming in barrel, high thermal efficiency and steam saving, which saves energy by 50% compared to the continuous Pre-expander Machine. Stable density and the uniform particle. Pre expander can be applied to copolymerization of EPS, EPMMA and STMMA simultaneously. Cost-effective.

1. The host unit

2. Famous Chinese brand control system in China (optional Siemens screen)

3. Discharge system

4. Automatic weighing system

1. Equipped with hot air drying system. Raw material without agglomeration, dry and uniform, shortening time ripening time.

2. The machine adopts PLC programmable controller and touch screen control,automatic material feeding system,automatic electronic weighing, automatic control of barrel’s temperature and air pressure and automatic sensing of material level to guarantee machine’s automatic circular production.

3. The computer memory stores commonly used foam density relative parameters, convenient for subsequent use.

4. This machine is cost-effective, safe and stable, easy maintenance.

What Is the Cost of a Lost Foam Casting Plant?

The Advantages and Disadvantages of Lost Foam Casting

Unlocking the Secrets of Lost Foam Casting

Material Selection for Lost Foam Casting

For more informations pls contact us!