- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

Through compressed air, the system controls high pressure tank automatic gun, and sends the pre-foamed beads into the high pressure tank.Top pneumatic control release valve closes. When the mould needs feeding, the system controls the feeding gun and automatically sprays the foam beads into the mould cavity, so that the beads distribute evenly in the mould cavity and reduce withe model defect. After feeding completed, returning starts, and send the remaining foam beads in the pipeline to the silo for the next use. It is especially suitable for products with high precision and thinner white models.

Product Structure

1. Pressure tank

2. pressure regulating valve

3. feed valve and release valve

4. Feeding gun

5. discharge ball valve

6. Feed gun (mold matching)

Product Performance and Characteristics

1. High degree of automation. One person multi machine operation, improving production efficiency of molding machine.

2. Material filling tight. Automatically change feed time and intermittent feed time.

3. Automatic material return, time be set accordingly. No resource waste.

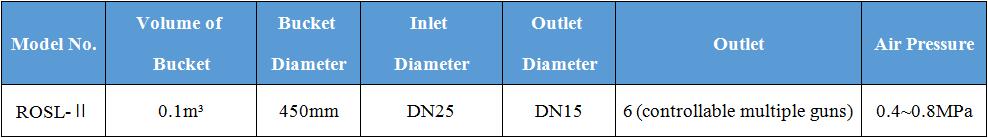

Technical Parameters