- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

Pneumatic conveying system is a dense phase pneumatic conveying device.Use the energy of airflow to transport granular materials, which can be carried in horizontal, vertical or inclined direction along the airflow direction in the closed pipe. Compressed air source is needed to provide power.

The device adopts intermittent gas-filled tank type dense phase conveying. The particles are added into the pressure tank in batches, and then ventilate the tank and loose the particles. When the inner pressure of the tank reaches a certain pressure, open the material valve and blow the particle material into the conveying pipe. The warehouse pump in and out of material each time is a working cycle.

Process Stages:

1. material feeding

2. fluidization compression

3. conveying

4. blowing

Product Structure:

Pneumatic conveying system is mainly composed of the feeding valve, single-control valve, telescopic device, bin pump, fluidized chamber, intake device, exhaust device, conveying pipeline, spherical elbow, supercharger, unloader, etc.

1. bin pump: one of the main components of the pneumatic conveying system. Bottom discharging mode. It receives material collected from the upper silo, and sets flow state inflatable plate (layer) at the bottom of silo pump and the nozzle jet fluidization, so that the material can be discharged.

2. fluidization chamber: material reaches boiling state. This device can reduce the volume of compressed air needed and transport the material more easily.

3. supercharger: unique design, replenish gas volume during transportation, and effectively prevent and solve the problem of gas plugging.

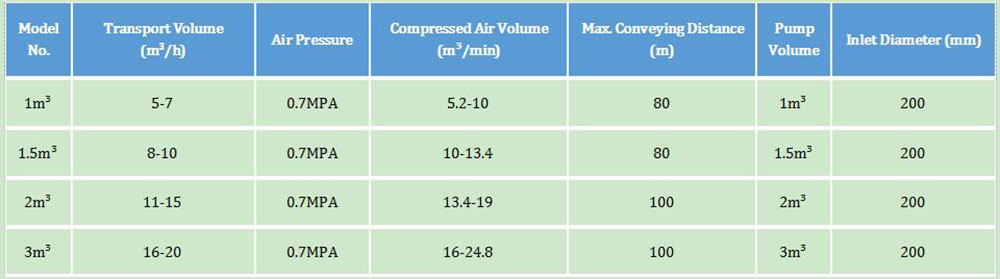

Model Selection and Technical Parameters:

(Note: the specific model is based on the actual design.)