- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

The movable shower type sand feeder is a sand feeding device for moulding of LFC line and film covering work. It is equipped with a mobile mechanism and has a small sand bucket designed to store a small amount of sand. It can meet the demand for two or three top sand feeding section. The main moulding section is below sand storage silo, which is used for bottom sand feeding and moulding of sand box, and top sand feeding is set behind moulding position. After feeding bottom sand, the movable movable shower sand feeder is be moved to top sand position. Yellow model is placed and the movable shower feeder is returned for moulding. At the same time, workers can move to the top sand position to carry out the film covering operation. After the plastic film and moulding are completed, the movable shower feeder is moved to top sand position for the last feeding. In this circulating way, moulding time is saved. Moreover, when the movable shower feeder is moved away, it leaves more space for moulding section, which provides favorable conditions for workers to operate.

Product Structure:

The shower sand feeder is mainly composed of runners, sand dropping bucket, guiding brackets, live pulling plate and cylinder. And each movable shower feeder is equipped with one fixed shower feeder, which is mainly composed of dust removal port, fixed plate, live pulling plate, lower frame, cylinder and guiding device.

The whole set of equipment is equipped with steel structure such as supports and trails.

Product Performance and Characteristics:

1. Feed sand evenly into sand box through shower type feeding method to ensure that every corner is filled.

2. It can be moved to next sandbox of moulding position to do film covering and top sand feeding during workers do moulding. The work rhythm is reasonably arranged and the moulding time is saved.

3. Through PLC control, it can be linked with the production line and vibrating table to realize automatic sand feeding and vibration of the sand box.

4. Concerning the layout, compared to automatic line, a moulding section with movable shower sand feeder not only can meet the whole moulding process, but also save one bottom section with same efficiency. This can reduce equipment cost of 1 bottom sand hopper, 1 bottom vibration platform, 1 unloaders and 3-6 sand boxes. The cost of the production line is greatly reduced.

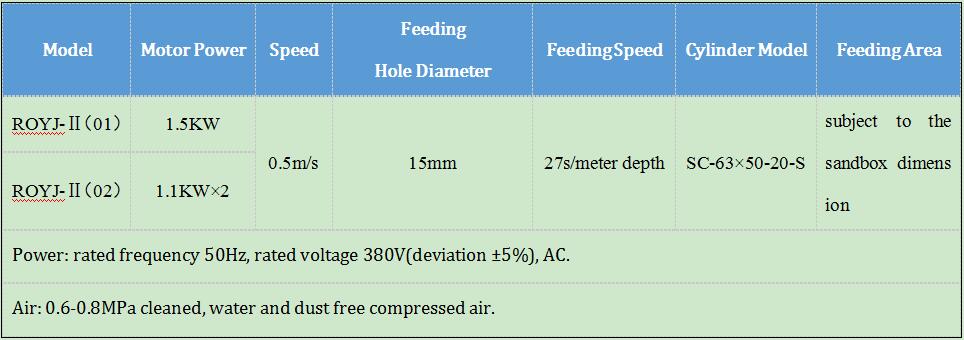

Model Selection and Technical Parameters:

(Note: the specific model is based on the actual design.)