- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

The bottom flip hydraulic turnover machine is the equipment used in the black area LFC to turnover boxes and dropping out castings. It has features of high turnover frequency and high level of automation because it turns boxes on production line and return to position after turnover. Hydraulic energy converted to mechanical energy, good adaptability to the environment and stable operation effect. Bottom clamping design makes clamping effect better, operation safer and structure simpler.

Product Structure:

The bottom flip hydraulic turnover machine mainly consists of hydraulic pump station, turnover body, lifting cover, machine frame, hydraulic oil circuit, executive cylinder and turnover control box.

Product Performance and Characteristics:

1. Hydraulic energy be converted to mechanical energy. Stable operation, strong environmental adaptability, convenient maintenance and simple handling.

2. The hydraulic lock is equipped on turnover cylinder, clamping cylinder and cover cylinder, which makes the equipment stop in real time in the process of action and avoids all kinds of dangerous conditions caused by the sudden stop of the power failure. Action can be done manually after the power failure is restored.

3. The flip body is designed with bottom type clamping, which is more safe and stable.

4, Online turnover operation to save time greatly.

5. The control system is integrated in control cabinet. For easy operation, the control box can be placed near the equipment.

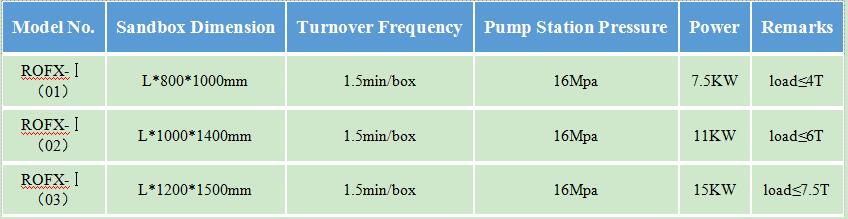

Model Selection and Technical Parameters:

(parameter for reference, subject to change without mark)

Note: Bottom flip hydraulic turnover machine is non-standard, above are our common used models, could be designed according to customer site.